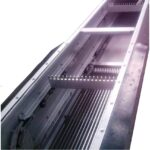

DESCRIPTION AND CHARACTERISTICS OF THE DET29N HEAVY SERIES AUTOMATIC BAR SCREEN

Unit suitable for installation in medium and large-sized liquid channels. Its purpose is to prevent solids in the water flow from passing, retaining them at the bars from where they will be collected by special combs installed on chains and deposited by means of a discharge ramp into the outlet. From there, they are moved into a waste container, auger transporter - compactor or conveyor belt.

Depending on the distance between the shims which comprise the bars, the retention of solids will be greater or lesser per the pitch. Thus, we can divide the DET29N heavy series automatic bar screens into Thick, Medium and Fine Screens.

MAIN COMPONENTS OF THE HEAVY SERIES AUTOMATIC BAR SCREEN

FRAME

A single unit made of steel and fully enclosed. It serves as a support to all the moving parts, automatism, bars and discharge plate. It has adjustable supports on either side to fix onto the civil works and two pieces of EPDM seal to adapt to the channel walls.

DRIVE UNIT

This consists of a geared motor and a drive shaft with two sprocket wheels flush to it; these interlock with the two lateral conveyor chains, where the cleaning combs are attached.

BARS

these comprise rectangular cross-section shims which form a variable pitch (minimum of 12 mm) mechanically welded screen.

SET OF CHAINS, COMB AND COMB CLEANER

The cleaner combs clean the light series automatic bar screen. Their tops are attached to the conveyor chains which, when moving downwards, reach the lower part of the light series automatic bar screen and with a simple spinning motion go between the bars. Moving back upwards, they drag all the trapped waste with them.

A minimum of two combs are installed, though this number may rise depending on the discharge height. On the upper part, the comb cleaner unit is installed. This comprises a nylon scraper coupled to a metal profile and all supported by swing-brackets that expel the waste deposited on the comb cleaners.

DISCHARGE PLATE

Of variable size depending on the discharge point and water height. Discharge from the light series automatic bar screen occurs at a suitable height above the channel wall.

AUTOMATISM SYSTEM

To operate the light series automatic bar screen automatically, there needs to be a control box which can be equipped to work on a time-delay or by means of a pressure drop. There must also be an overload protection system (torque limiter).