The DET21N Slurry Thickener is designed to be installed in circular enclosures. It is used to concentrate settled solids and clarify liquids.

The slurry thickener essentially consists of a round tank with a tapered base and a slope towards that base. The mechanical units to pull the slurry towards the central cone down which it passes are mounted on the enclosure. Meanwhile the clarified water flows down the spillway to a peripheral channel to continue on with the consequent treatment process.

The main purpose of the process is to improve the efficiency and economy of the later processes. By increasing the concentration of solids, we considerably reduce the volume, thus making significant savings in removal costs.

MAIN COMPONENTS OF THE DET21N SLURRY THICKENER

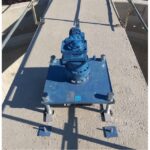

DRIVE UNIT

The central drive consists of a geared motor unit which works directly on the main shaft. It is advisable to install a torque limiting device to forestall any overloading that might damage or deteriorate the equipment.

MAIN SHAFT

Comprised of a pipe of variable size and thickness (with the relevant reinforcement) attached to the drive unit using flanges. The shaft powers the bottom scrapers and thickening rods. Support brackets are securely attached to the lower part of the shaft on the slurry thickener.

SUPPORT BRACKETS

Carbon or stainless steel mechanically welded metallic structures which are bolted onto the central shaft and serve as a support mechanism to the bottom scrapers.

BOTTOM SCRAPERS

Structured in steel profiles comprising two diametrically opposed radial brackets with the scrapers attached to the lower section. These have elastomer strips attached which will sweep the depths.

THICKENING RODS

Made from cold-rolled steel, they are installed and suitably braced on the scraper brackets.

CENTRAL DEFLECTOR BELL

Water enters through the upper section of the deflector bell, located in the centre and almost completely submerged. The purpose of this bell is to remove all possible chop in the incoming flow and send the liquid downwards.

ACCESSORIES OF THE DET21N SLURRY THICKENER

- Central walkway: Attached diametrically; support for the whole slurry thickener unit. Built with rolled steel profiles (handrails and framework included), it is inserted in the walls of the enclosure.

- Electric torque limiter module.

-

Floating particle removal and collection system.

- Peripheral spillway and deflector.